Groover Roofing & Siding, Inc. installs shingled, EPDM, and TPO commercial roof systems. Because many commercial roofs are flat roofs, EPDM and TPO are two of the most popular choices. We feature commercial grade products manufactured by Mule Hide and GAF and offer high-end manufacturer backed warranties with all our commercial roof systems.

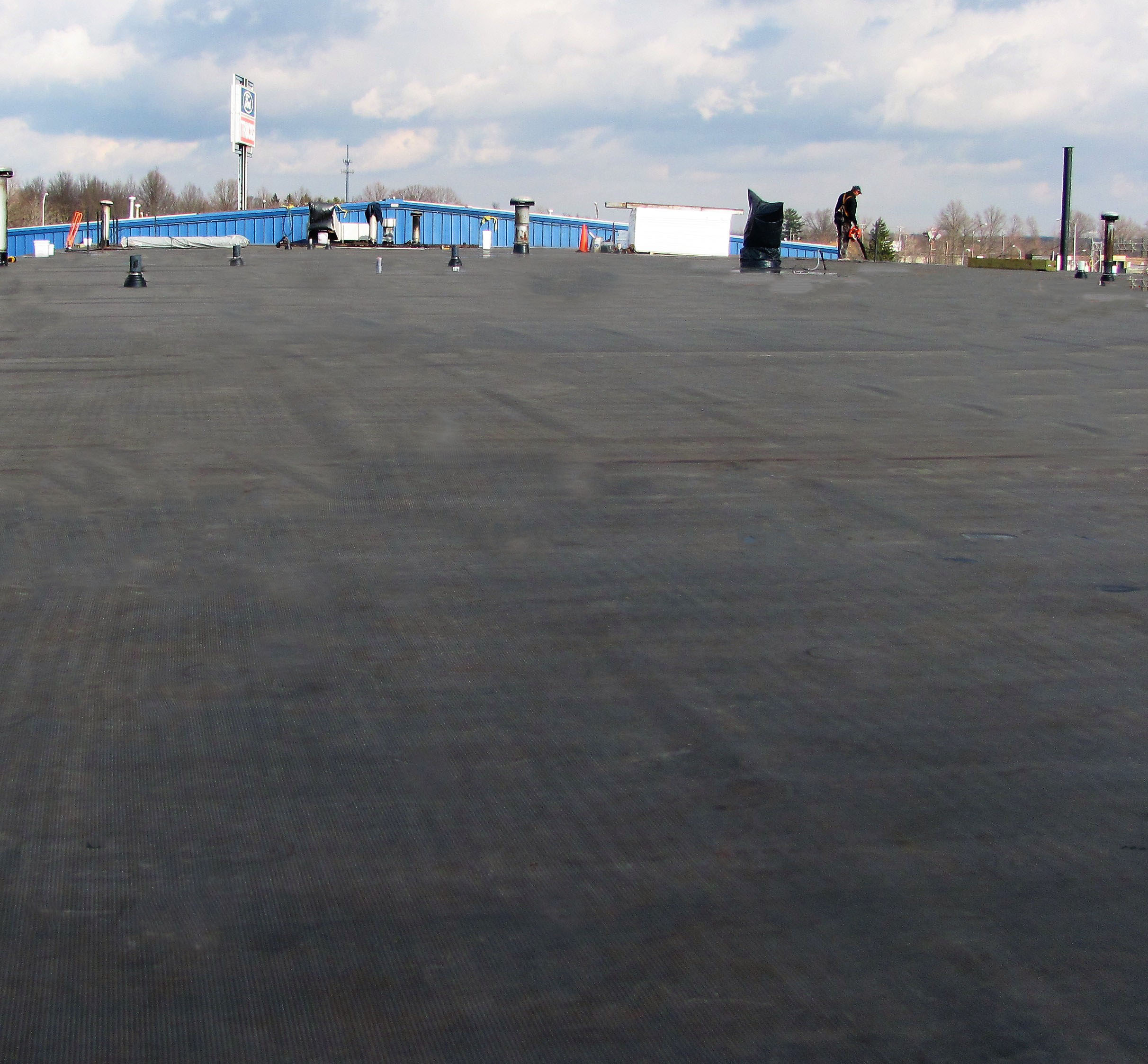

Our most popular flat roof option, EPDM (Ethylene Propylene Diene Monomer), is a high-performance synthetic rubber membrane designed to be resistant to tear, puncture, impact, and normal roof traffic. Insulation is mechanically fastened, then the rubber membrane is fully adhered. Instead of mechanically fastening the rubber membrane like many companies do, Groover Roofing & Siding fully adheres EPDM to prevent lifting from wind or other acts of nature. EPDM is generally the most common commercial flat roof system, as it is affordable, easy to repair, and has a long life expectancy.

Thermoplastic Polyolefin, or TPO, requires a more complex installation process than EPDM. The insulation is mechanically fastened, the seams and penetrations are heat welded, and the TPO is fully adhered. TPO seam strengths are generally three to four times stronger than EPDM seams. These single-ply roof systems are quickly growing in popularity, as the white roof material can help reduce interior energy costs significantly.

A semiannual Maintenance Program is included at no additional cost for the first two years on all complete commercial flat roof replacements installed by Groover Roofing & Siding. We also offer a semiannual Maintenance Program on existing commercial roofs.